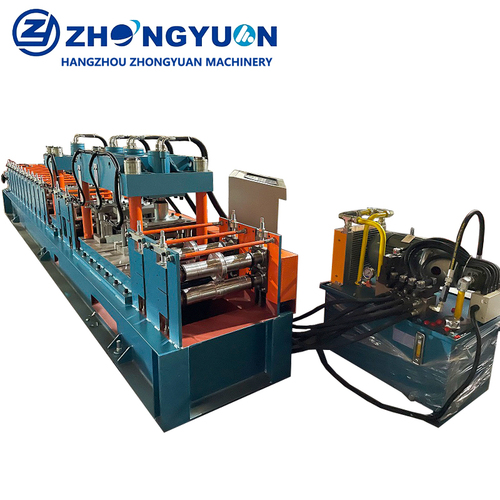

C U stud and track roll forming machine

Product Details:

- Type C U stud and track roll forming machine

- Material Steel coil sheet

- Capacity 25-30m/min m3/hr

- Computerized No

- Automatic Grade Automatic

- Control System PLC Control

- Rolling Speed 25-30 m/m

C U stud and track roll forming machine Price And Quantity

- 1 Set

- 33000 USD ($)/Set

C U stud and track roll forming machine Product Specifications

- hydraulic cuttingh

- 25-30 m/m

- 3000 Kilograms (kg)

- C U stud and track roll forming machine

- No

- 415 Volt (v)

- 4.8 x 1.1 x1.6 Meter (m)

- PLC Control

- 25-30m/min m3/hr

- blue

- Steel coil sheet

- 3 year

- Automatic

- 0.4-0.5 Millimeter (mm)

C U stud and track roll forming machine Trade Information

- Ningbo or Shanghai port

- Telegraphic Transfer (T/T)

- 20 Set Per Month

- 90 Days

- PACKAGE: 1. need about 1*20GP container for loading one set machine completely; 2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film; 3. Spare parts and some small parts packed in plastic tooling box; 4. All Components Fixed by steel wire with Container.

- Asia, Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America

- All India

- CE SGS

Product Description

Stud & track roll forming machine

Specifications

Weight Capacity Of Decoiler: 3Ton

Main Motor Power: 5.5Kw

Hydraulic Motor Power: 2.2Kw

Forming Station:15stations ( depend on profile drawing )

Forming speed: 25-35 m/min

Control System: Mitsubishi PLC and transducer (Japan)

Type of Cutting: Length-set cutting and post forming style

Guarantee term: 24 months

Description of stud and track roll forming machine

1. Metal stud and track roll forming machine is the most common machine to produce cold rolled C stud and u track profiles. It is the most popular machine in light building construction area.

2. We are professional manufacturer of metal stud and track roll forming machine and have lots successful experiences. Our roll forming machine for C stud and u track can make the C stud and u track from thickness 0.4mm-0.7mm. Very portable!

3. The whole line of metal stud and track roll forming machine include the automatic decoiler or manual decoiler for 3ton coils , roll forming machine include the guide& feeding device, cutting blade drived by hydraulic power and auto stacker or manual stacker for finished products.

4. This line can be automatic running by inputting the length and batches in the PLC system.

5. The strong H beam base is treated to avoid the vibration when working.

6. All the rollers are hardness quenched to guarantee the life

7. The human computer interface operate system will save human source to operate the production line.