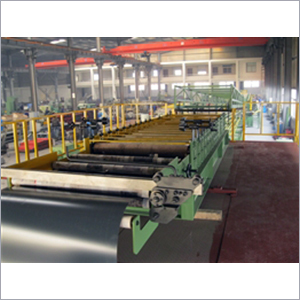

Continuous PU Sandwich Panel Production Line Machine

Product Details:

- Operating Type Automatic

- Dimension (L*W*H) 90X15X15 Meter (m)

- Weight (kg) 145 Tonne

- Warranty 12 months

- Usage & Applications use to make sandwich panel roof or wall.

Continuous PU Sandwich Panel Production Line Machine Price And Quantity

- 600000.00 - 1100000.00 USD ($)/Set

- 1 Set

Continuous PU Sandwich Panel Production Line Machine Product Specifications

- 90X15X15 Meter (m)

- 12 months

- use to make sandwich panel roof or wall.

- Automatic

- 145 Tonne

Continuous PU Sandwich Panel Production Line Machine Trade Information

- Letter of Credit (L/C), Telegraphic Transfer (T/T)

- 2 Set Per Month

- 180 Days

- Western Europe, North America, Eastern Europe, Central America, Asia, Africa

- All India

- ISO, CE

Product Description

Having carved a distinct niche in this domain, we are engrossed in manufacturing, exporting and supplying a quality assured Continuous PU Sandwich Panel Production Line Machine. Offered machine finds application in transportation, automotives as well as building construction where high structural rigidity and low weight is needed. This is manufactured in accordance with industry norms at well equipped unit under the observation of skilled professionals. Along with this, the provided Continuous PU Sandwich Panel Production Line Machine can be purchased from us at nominal prices.

Key Points:

- Very high strength

- Negligible maintenance

- Superior finish

- Excellent rigidity

| Technical parameters | ||

| Item | Specification | |

| Raw Material | Type | Color steel coil |

| Thickness(mm) | 0.4-0.7 | |

| Yield strength(mpa) | 235-345 | |

| Max. Width | 1250 | |

| Sandwich Panel | Panel width | 950-1000mm (according to profile requirement) |

| Mini thickness | 40mm (corrugated sandwich panel) | |

| Max. Thickness | 150mm (corrugated sandwich panel) | |

| Min. cutting length | 3 m | |

| Max. Stacking length | 15m | |

| Working height | 1150mm (height of panel coming out) | |

| PU forming density | ABOUT 40 kg/m3 | |

| Pressure for foaming | 150-200 bar | |

| Effective length of double belt conveyor | 23m | |

| Roller material | 45# steel , coated with Chrome | |

| Shaft for rollers | Solid shaft with 72mm,processed with cylindrical grinder | |

| Forming speed(m/min) | 3-7m/min (adjustable) | |

| Speed adjusting mode | Misubishi frequency transformer | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 mould steel | |

| Length measurement | Nemicon Encoder | |

| Control mode | Mitsubishi PLC | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Total power(kw) | About 100KW | |

|

| ||

|

|

| |

| Hydraulic Uncoiller | 2set | |

| Platform for forming machine | 1set | |

| Roll Forming System | 2set | |

| Foaming system | 1set | |

| Double Belt Laminator | 1set | |

| Cutting System | 1set | |

| Stacking system | 1set | |