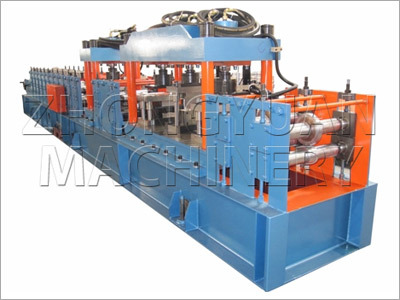

Cold roll forming line

Product Details:

- Computerized Yes

- Automatic Grade Automatic

- Rolling Speed 30-35 m/m

- Cutting System Hydraulic cutting

- Cutting Thickness 0.3-0.8 Millimeter (mm)

- Voltage 415 Volt (v)

- Color Blue

Cold roll forming line Price And Quantity

- 23000-38000 USD ($)/Set

- 23000.00 - 38000.00 USD ($)/Set

- 1 Set

Cold roll forming line Product Specifications

- 30-35 m/m

- 415 Volt (v)

- 12months

- 10.3*1.6*1.6 Meter (m)

- Yes

- 0.3-0.8 Millimeter (mm)

- 9500 Kilograms (kg)

- Blue

- Automatic

- Hydraulic cutting

Cold roll forming line Trade Information

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 20 Set Per Year

- 90 Days

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Africa, Asia

Product Description

Due to our hi-tech production lines, we are able to manufacture, export and supply supreme quality Iron Roof Roll Forming Machine. The provided machine is best suited for forming sheet, strip and coiled metal into uniform cross-section. We offer this machine in varied specifications at reasonable rates. The provided machine is manufactured using optimum grade components by diligent technical experts. Our valued patrons can get this Iron Roof Roll Forming Machine at affordable prices from us.

Features:

- Generates low noise

- Ease in installation

- Modular construction

-

Easy to operate

Iron Roof Roll Forming Machine

|

Item |

Specification |

|

|

Material |

Type |

Pre-painted steel coil & galvanized coils |

|

Thickness (mm) |

0.4-0.7 |

|

|

Yield strength (mpa) |

235-345 |

|

|

Roller material |

45#Chrome steel |

|

|

Forming speed(m/min) |

About 20-25 |

|

|

Cutter material |

Cr12 mold steel |

|

|

Main motor power (kw) |

7.5 kw (Depend on final design) |

|

|

Hydraulic station power |

2.2 kw (Depend on final design) |

|

|

Uncoiler's loading capacity |

Max. Capacity: 5000kgs (can be increased to be 10T) |

|

|

Machine`s size |

About 12 x 1.6 x 1.6m (Depend on final design) |

|

Machine components:

- Decoiler (manual decoiler and hydraulic decoiler for option) : 1 set

- Feeding & guiding device : 1 set

- Main roll forming machine : 1 set

- Hydraulic cutting system : 1 set

- Controlling system : 1 set

- Run out table (auto. Stacker for option) : 2 pcs

Process flow:

Decoiler -- Feeding & Guiding -- Roll Forming-- Hydraulic Cutting Product to Run Out Table

Can not find the machine you need? Why not customize it!

We have:

- 12 years experience in making roll forming machine

- 15 years experience engineers

To customize machine, we would love to know:

- Profile drawing

- Raw material: the width(1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

- Voltage: designed per your requirement

- Configuration requirement: Hydraulic or manual decoiler/ stacker