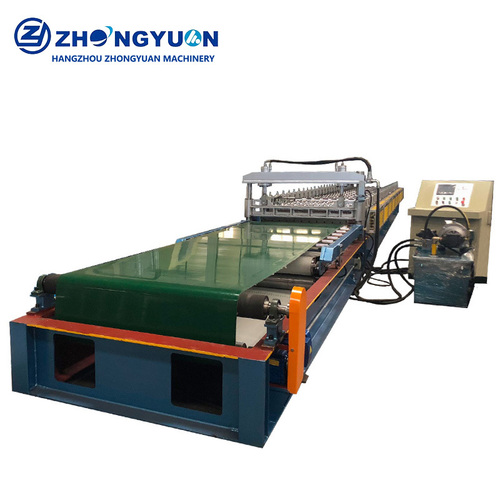

Steel Roof Profile Forming Machine

Product Details:

- Computerized Yes

Steel Roof Profile Forming Machine Price And Quantity

- 1 Set

- 36000.00 - 110000.00 USD ($)/Set

- 36000-110000 USD ($)/Set

Steel Roof Profile Forming Machine Product Specifications

- Yes

Steel Roof Profile Forming Machine Trade Information

- 20 Set Per Year

- 90 Days

Product Description

Features:

- Longer working life

- Vibration less functioning

- Maximum production output

- Power efficient

Steel Roof Profile Forming Machine

Why choose this machine?

- Certificate: ISO 9001, CE,

- Lifetime services

- 72mm diameter solid steel shaft. Roller cover with 0.05mm chrome; Lifetime>10years.

- Introduced Mitsubishi PLC with touch screen to machine controll system.

- Heat treatment:Cutting blade. Quenched treatment: Cr12 mould steel cutter

- Product cut-to-length.

- Technician overseas installing and training available

| Item | Specification | |

| Material | Type | Pre-painted steel coil & galvanized coils |

| Thickness (mm) | 0.4-0.7 | |

| Yield strength (mpa) | 235-345 | |

| Forming speed(m/min) | About 20-25 | |

| Speed adjusting mode | AC Frequency | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 mold steel | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor power (kw) | 7.5 kw (Depend on final design) | |

| Hydraulic station power | 2.2 kw (Depend on final design) | |

| Uncoiler's loading capacity | Max. Capacity: 5000kgs (can be increased to be 10T) | |

| Machine`s size | About 11*1.6*1.6m (Depend on final design) | |

Components

| Decoiler (manual/ hydraulic decoiler for option) | 1set |

| Feeding & guiding device | 1set |

| Main roll forming machine | 1set |

| Hydraulic cutting system | 1set |

| Controlling system | 1set |

| Run out table (auto. Stacker for option) | 1.5m/ pc, 2 pcs |

Process flow:

- Decoiler -- Feeding & Guiding -- Roll Forming-- Hydraulic Cutting – Product to Run Out Table

Packing:

- One 40feet container for loading one set machine with decoiler.

- Main machine body and decoiler is load naked (tighten to container with steel wire rope).

- Spare parts and operating tools are loading in tooling box.